Flat Pack Containers For Sale

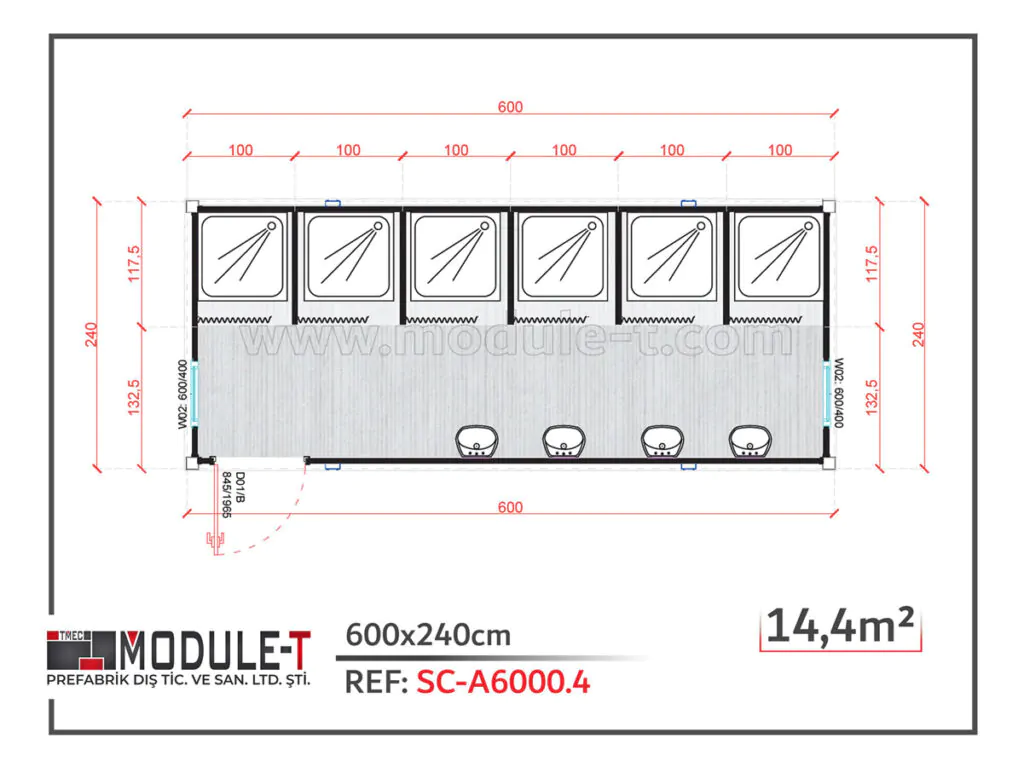

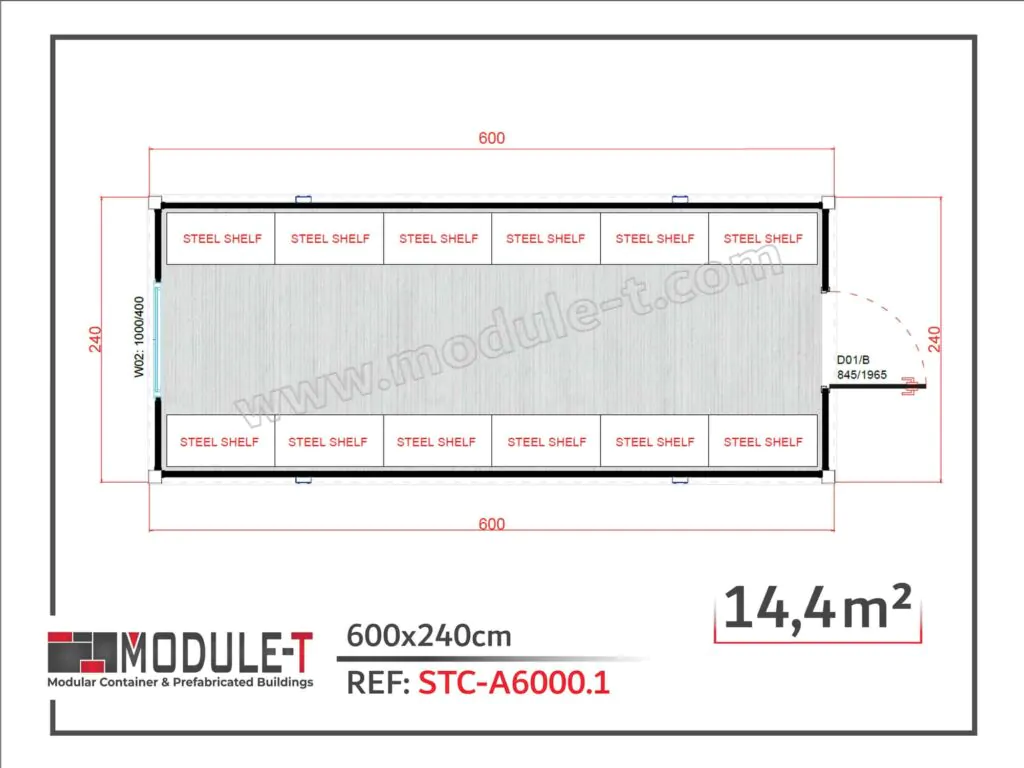

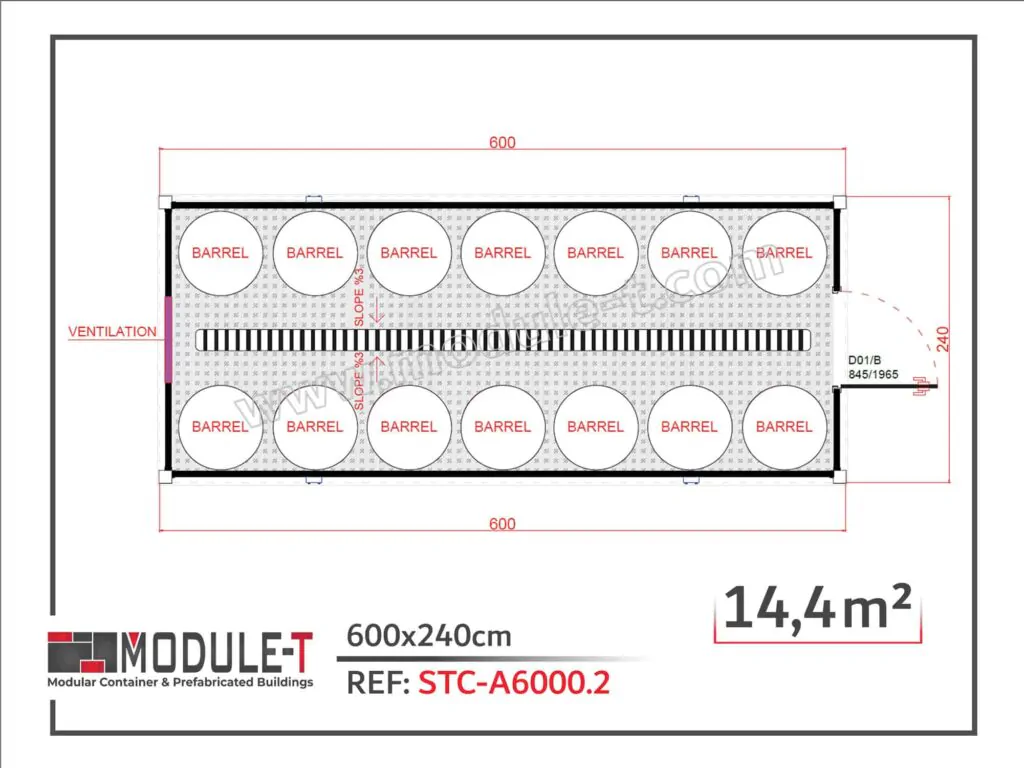

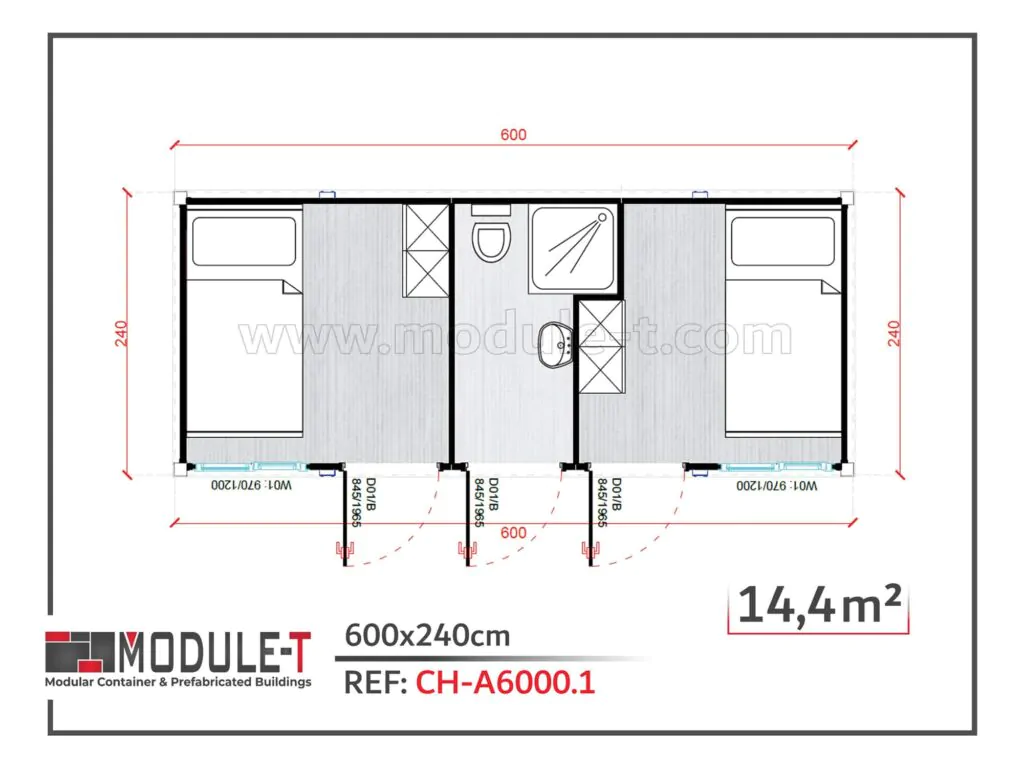

Flat pack containers are modular, prefabricated structures designed for portability, affordability, and quick assembly, making them ideal for construction, mining, industrial camps, hospital facilities, and emergency or military accommodations. Produced by Module-T, a globally recognized manufacturer, these containers adhere to international building codes, ensuring durability and compliance with seismic and cyclonic standards. Available in customizable designs, they serve diverse purposes, including office spaces, housing, and locker rooms, offering efficient insulation, competitive pricing, and easy transport by land or sea. With over 15 years of expertise, Module-T provides versatile, stackable, and stand-alone solutions tailored to meet specific needs.

Flat Pack Container Price

The cost of flat pack containers varies depending on factors such as size, customization, and transportation:

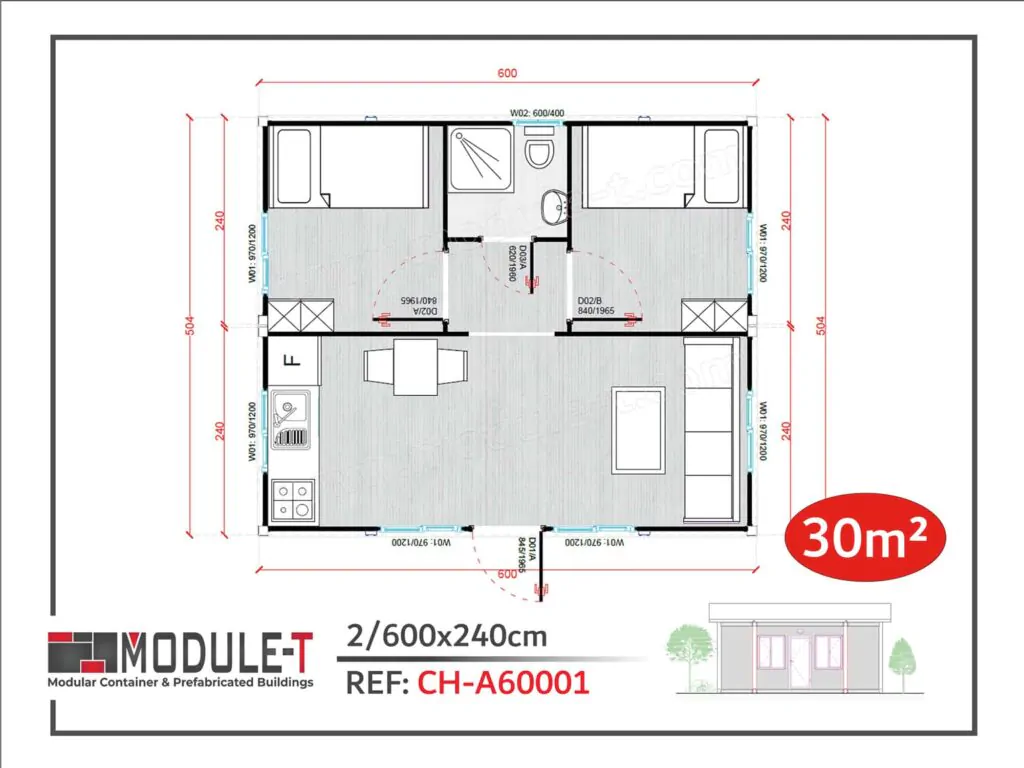

- Container Size: We offer a wide range of standard and custom-built containers in different sizes, each with a corresponding price.

- Insulation: The type and thickness of insulation, such as polyurethane, rock wool, or expandable polystyrene (ranging from 50mm to 100mm), affect the price and are tailored to the climate where the container will be used.

- Custom Additions: Features like air conditioning, solar panels, heating systems, advanced security options, and interior modifications can increase costs.

- Transportation: They are efficiently packed for shipping, varying transportation costs based on the destination.

For instance, a 4m flat-pack container will have a different price point than a 6m flat-pack office container. Additional features, like enhanced insulation or specific interior fittings, can also impact the cost. However, these containers offer substantial savings compared to conventional building methods, making them a cost-effective solution for many projects.

Why Choose Module-T for Buying Flat Pack Containers?

Module-T is a leading provider of high-quality flat pack and modular containers for sale, with over 15 years of experience delivering to over 120 countries. We offer reliable, cost-effective solutions tailored to our clients’ specific needs. Our flat pack containers are designed with precision, ensuring they meet international building standards and can withstand various environmental challenges. We also provide a comprehensive warranty and after-sales service to ensure your satisfaction with our products.

Whether you need a flat pack showroom container, house, office, or for a storage solution, Module-T provides comprehensive support from design to assembly. We also offer a variety of options, including modular containers, office units, and storage containers for sale, making us a trusted choice for all your modular building needs.

For more information on our range of flat pack containers, or to receive a free quote, please contact us today. Explore our offerings, including flat pack container house prices to find the perfect solution for your needs.