Frame and Structure :

The structure is formed from aluminum or rigid steel to ensure safety and strength.

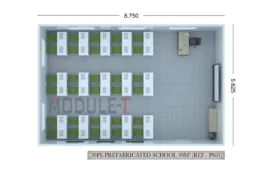

The modular construction industry has evolved rapidly, with many public and commercial facilities now built using prefabricated structures.

One of the most notable trends is modular and prefabricated hotels, which offer superior quality, cost savings, faster installation, and enhanced sustainability compared to traditional brick-and-mortar hotels.

At Module-T, we manufacture high-quality modular and prefabricated hotel units. Our extensive range includes prefabricated rooms, suites, and complete hotel facilities designed to meet the needs of hotel developers worldwide. Whether expanding an existing property or building a fully portable hotel from the ground up, our team is here to help. Explore the specifications, features, and applications of our modular and prefabricated hotels below to see how we can bring your project to life efficiently and affordably.

The structure is formed from aluminum or rigid steel to ensure safety and strength.

Sandwich panels with high-grade rock wool, polyurethane, or polystyrene foam insulations are used for the walls to ensure optimal thermal and acoustic performance.

There is a choice of metal panels or engineered wood.

We can include cladding or siding to the exterior of prefab hotels to make them more aesthetically pleasing and offer better protection from the elements.

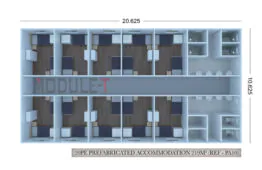

There are several choices, including ensuite prefabricated hotel rooms with bathroom buildings, sinks, showers, and WCs.

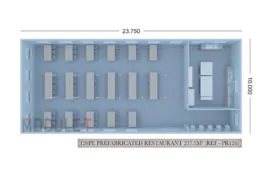

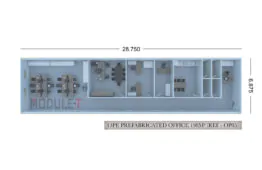

They can be customized in many ways. Popular additions include air conditioning, heating, Wi-Fi, networking sockets and cables, and cabinetry. Many open and closed rooms can serve as bedrooms, receptions, board or conference facilities, modular site facility buildings, kitchens, restaurant buildings, cafes, bars, leisure facilities, and gymnasiums.

A modular prefabricated building can add prefabricated bathrooms, shower rooms, locker facilities, sports and communal areas, and gymnasiums to a traditional hotel.

They are often used as the basis for roadside and service station hotels.

During large construction projects, many contractors, laborers, visiting management, and their families require temporary prefab accommodation buildings. Portable hotels are ideal for this purpose, as they can be dismantled and moved elsewhere once the project ends.

Affordable prefab hotel buildings are far greener than the traditional build process. A modular building only requires a light foundation, meaning minimal damage is done to the land it is placed on. The remote manufacturing process also reduces harmful emissions from heavy machinery, resulting in less onsite disruption.

The modular construction industry has grown rapidly, with many public and commercial facilities embracing modular and prefabricated hotel buildings. A leading trend within this sector is the use of prefab hotels for their superior quality, cost-efficiency, quick assembly, and sustainability, making them an ideal alternative to traditional resort construction methods.

At Module-T, we specialize in designing and manufacturing modular hotel rooms and prefab hotels for sale, delivering projects worldwide. Our logistics team excels in transporting and assembling prefabricated hotels, including projects across the USA and internationally. Each building section is carefully flat-packed into 40-foot containers, pre-painted, and prepared for easy utility connections upon arrival. We provide connection kits and lifting hooks to simplify on-site setup, ensuring smooth and quick assembly.

We also assist with site preparation, advising on the necessary groundwork before the hotel components arrive. Modular hotels can be installed on basic cement baseplates or beams and assembled in just a few days. For larger-scale developments, we can arrange for a specialized assembly team to be present on-site. Explore our range of modular and prefabricated hotels to find the perfect solution for expanding your existing property or launching a portable hotel anywhere in the world.

Prefab hotel construction is commonplace in many countries. Because prefabricated buildings only require light foundations, they cause less environmental damage, so their sustainability benefits are now highlighted. Advances in the manufacturing process and the materials used also mean you receive a high-quality build at a very reasonable price.

The sustainability and cost of modular and prefabricated hotels are just two attractions; the speed with which we can manufacture and deliver portable hotels is also a great benefit, as you can usually have the premises up and running in weeks.

Today, many architects and designers create attractive, fully equipped prefabricated hotels by customizing the interior and cladding the exterior. From eco-lodges to highway service motels, the scope for modular hotel construction is growing, and they now present a savvy alternative to a conventional hotel.

The construction of any hotel or commercial premises is costly. However, one of the main reasons many use a modular hotel manufacturer is the price, as we can rapidly design and supply bespoke prefabricated hotels for significantly less than their brick-built counterparts.

Although we produce many standard modular and prefabricated hotels, we rarely make the same two. For this reason, the price of prefabricated hotel rooms and prefab hotel construction differs according to several factors.

First, the size and type of building must be carefully considered, whether you are developing small or luxury hotels or larger modular site facilities. Customizations such as interior and exterior design enhancements, insulation levels, and additional features can impact both functionality and aesthetics. We also factor in the cost of transporting the modular hotel from our factory near Istanbul to your site.

As a well-regarded modular hotel manufacturer, we are known for supplying high-quality modular and prefabricated hotels. Throughout our build process, we use the latest technology to ensure each section of a portable hotel is made according to the agreed design plans and of a consistent quality that meets EU and US building codes and regulations.

Our team works individually with all clients, and we are available throughout the design, build, and assembly process to offer support and ensure the modular hotel construction meets your needs and exceeds your expectations. If you are looking for reliable modular hotel builders or the best modular hotel construction companies, please consider our services and contact us for a free quote.

Yes, our range of modular and prefabricated hotels can be moved. Their innovative modular design is lightweight, meaning each module can be dismantled and relocated, or new modular buildings can be used to extend the premises if necessary.

Yes, you can include many appliances in the designs of modular and prefabricated hotels. Heating and cooling systems, internet, telephone or intercom systems, and even smart hotel or home features can all be added as desired.

Yes, one of the main advantages of a prefab hotel construction is its modular design, which means it can stand alone, be stacked, or placed side by side and connected as required.

Our modular and prefabricated hotels can usually be assembled on a light cement base plate or beams, meaning minimal groundwork is needed in advance. The chassis and sections come with lifting hooks for easy placement, and a connection kit is supplied if you intend to connect or stack the buildings.

All Module-T modular and prefabricated hotels are designed to be safe. Throughout the manufacturing process, care is taken to ensure the quality of our prefabricated hotels, and our technology ensures the building you receive adheres to international building codes and regulations.

The cost of modular and prefabricated hotels depends on multiple factors, including the size, design, number of rooms, and level of customization required. Other considerations, such as insulation, transportation, and assembly services, can influence the overall investment. To receive a tailored quote based on your project’s specific requirements, please contact Module-T, and our team will provide a detailed breakdown.

To receive a quote quickly, please fill in the customer request form. Our sales representatives will contact you as soon as possible.

To receive a quote quickly, please fill in the customer request form. Our sales representatives will contact you as soon as possible.