Flatpack or Preassembled: Which Type of Modular Construction Should You Choose?

The ideal solution depends on several factors, including budget, logistics, and project timelines. Each project has unique priorities, meaning there is no one-size-fits-all answer. Flatpack containers are generally preferred for projects that rely heavily on sea transport to avoid the high costs of shipping fully assembled units. However, when the construction site is close to the manufacturing facility, the cost difference between flatpack and preassembled options becomes negligible, making preassembled solutions more practical due to their faster installation.

Time constraints are also a key consideration. Preassembled modular construction is better if the project has tight deadlines, such as opening a prefabricated school building, completing a construction site, or addressing an urgent housing need. Its quick installation helps meet pressing deadlines with minimal delays.

The Advantages of Modular Construction

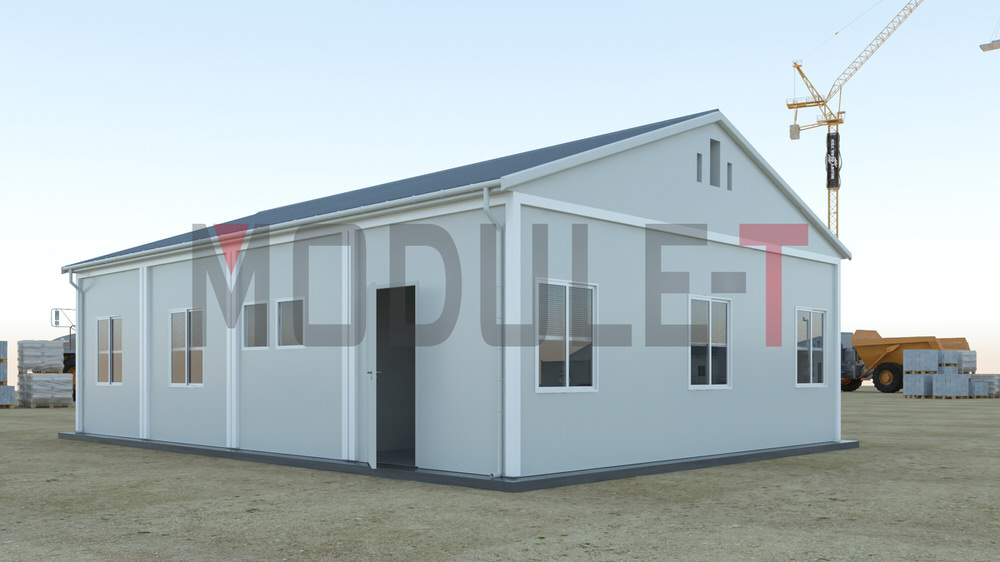

Modular construction offers numerous benefits over traditional concrete methods, combining cost-efficiency, speed, and flexibility. Whether preassembled or flatpack, this approach reduces labor costs and shortens installation time, making it ideal for fast-track projects. For example, prefabricated restaurant buildings can be set up quickly and efficiently, allowing businesses to start operations much faster than conventional construction.

Another key advantage is the sustainability of these systems. Built with eco-friendly materials, these structures are energy-efficient and meet environmental standards while requiring only light foundations. Most components are recyclable, minimizing ecological impact and aligning with companies’ sustainability goals.

They are also designed for durability and mobility. They can be expanded, relocated, or adapted, such as modular office buildings, to fit changing needs. Despite their flexibility, they are highly resistant to harsh conditions, with anti-hurricane and anti-seismic features. With customizable finishes and cladding options, the solutions offer functionality and appealing aesthetics for various temporary and long-term applications.

What Are the Limitations of Modular Construction?

While modular construction offers many advantages, it also has some limitations. One key challenge is design constraints, as prefabricated modules are built in standard sizes, which can limit architectural flexibility. This makes accommodating highly customized or complex designs harder than traditional construction.

Another area for improvement is transportation costs and logistics, especially for fully assembled modules. Shipping large units requires specialized trucks or containers; navigating tight urban areas or remote sites can take time and effort. Additionally, projects involving sea or long-distance transport may face higher costs.

On-site integration challenges can occur, particularly when buildings need to connect seamlessly with existing structures. Any misalignment in measurements can cause delays or additional work. Despite these limitations, modular construction remains a practical solution for many industries due to its speed, cost-effectiveness, and sustainability.

What is the Difference Between Modular and Non-Modular Construction?

The main difference between modular and non-modular (traditional) construction lies in the building process and delivery. In modular construction, the structure is prefabricated in a factory, either fully or partially, and then transported to the site for quick assembly. This method saves time and reduces labor costs, making it ideal for fast projects like modular restaurant buildings or temporary offices.

In contrast, non-modular ones are built entirely on-site, using concrete, brick, or wood materials. While it offers more design flexibility during construction, it is generally slower, more labor-intensive, and weather-dependent, leading to higher costs and delays.

Modular buildings also tend to be more sustainable. For example, modular hospitals are manufactured efficiently from pre-planned materials with minimal waste. On the other hand, non-modular construction is often more suited for complex, custom projects where detailed on-site modifications are required. Both approaches have strengths, but modular ones are increasingly favored for projects requiring speed, scalability, and eco-friendly solutions.