Dimensions:

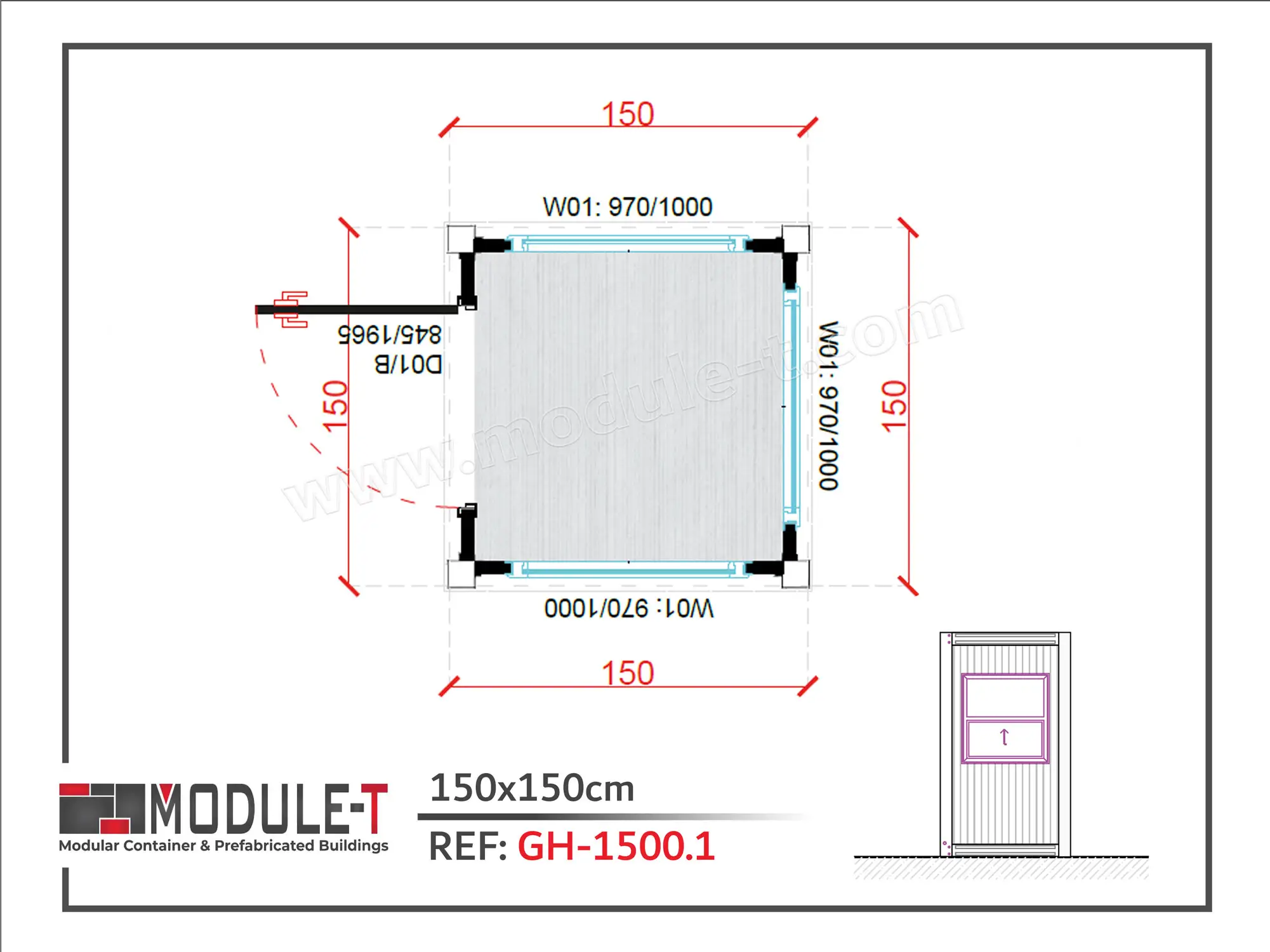

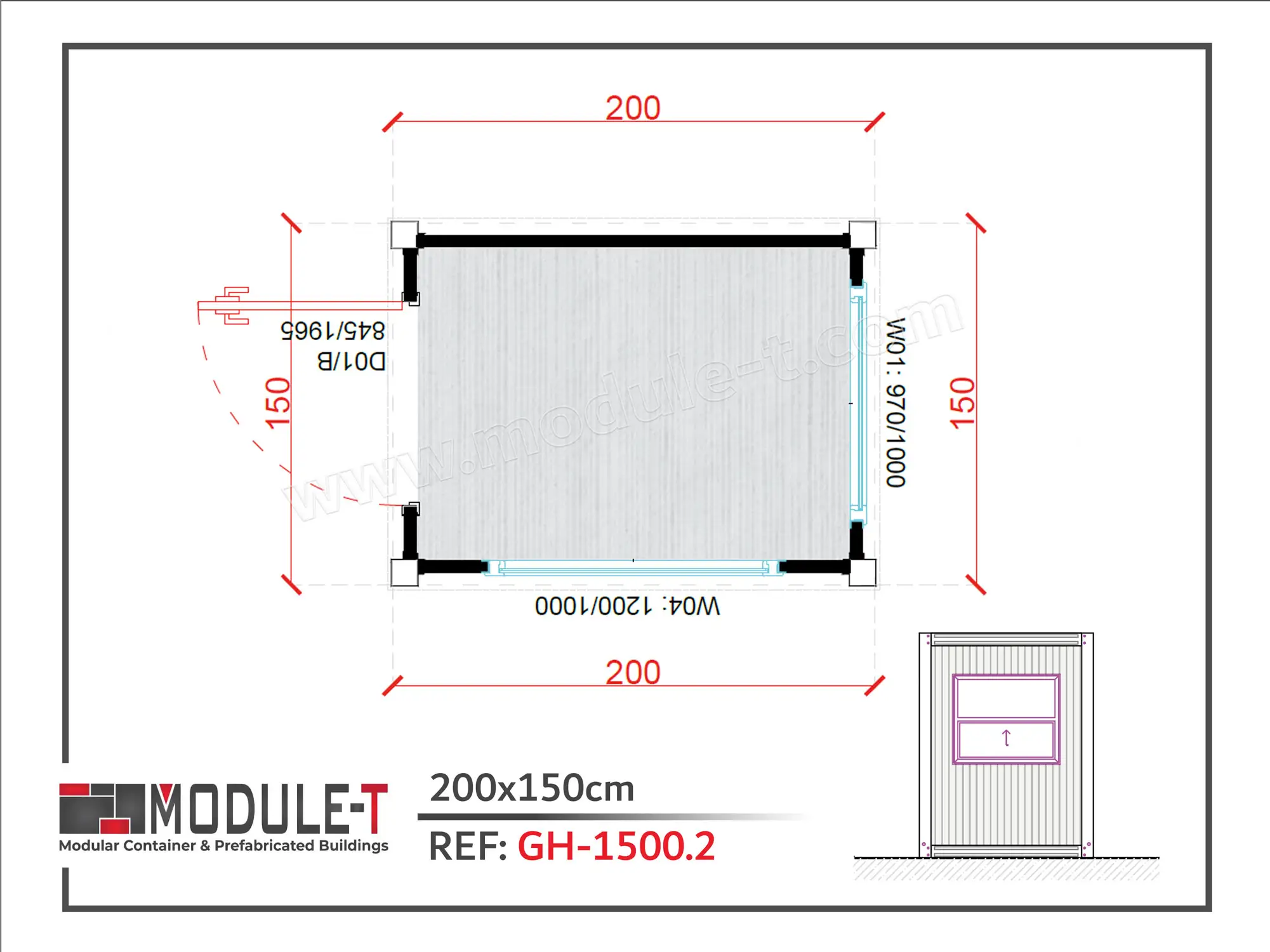

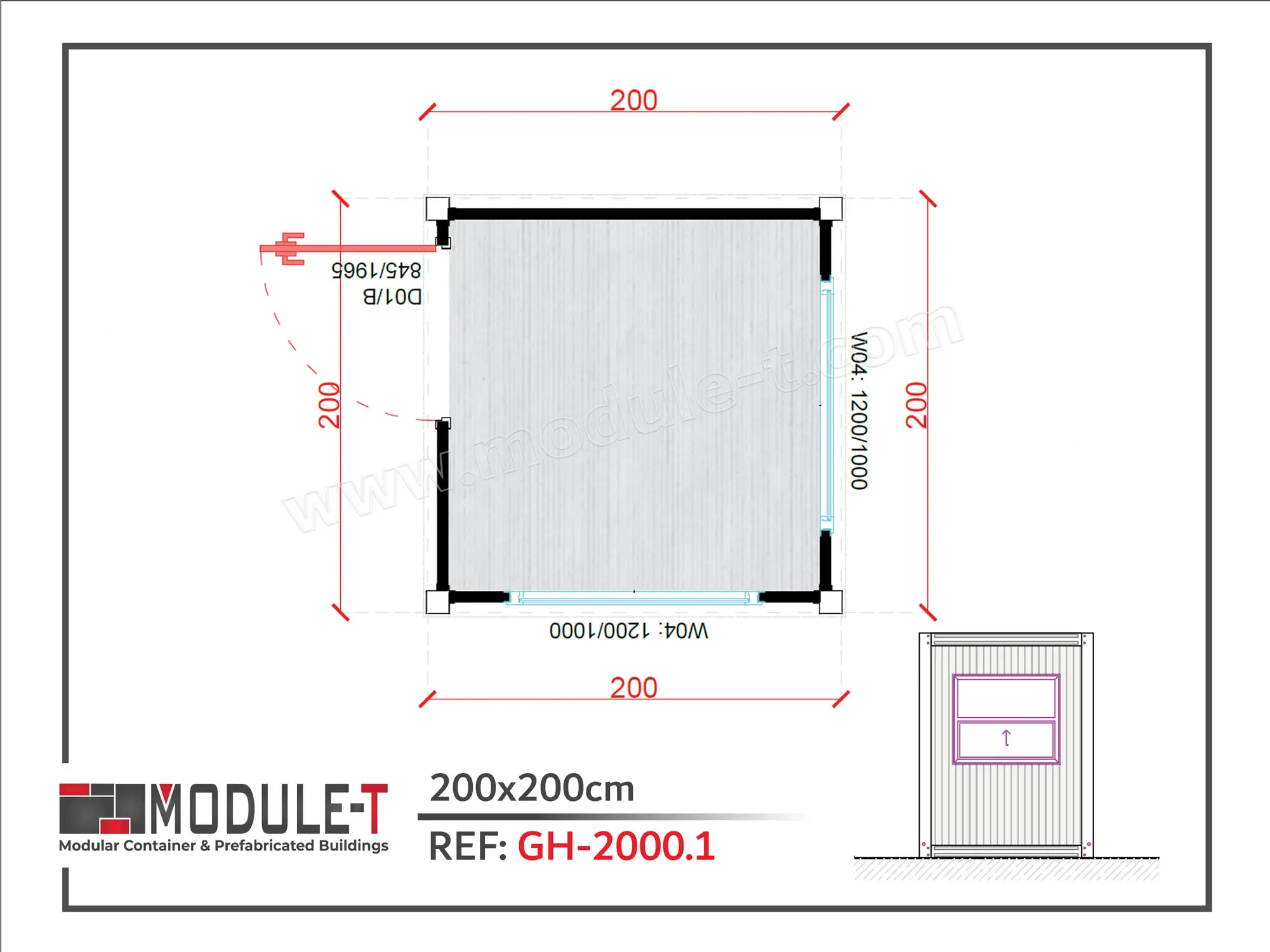

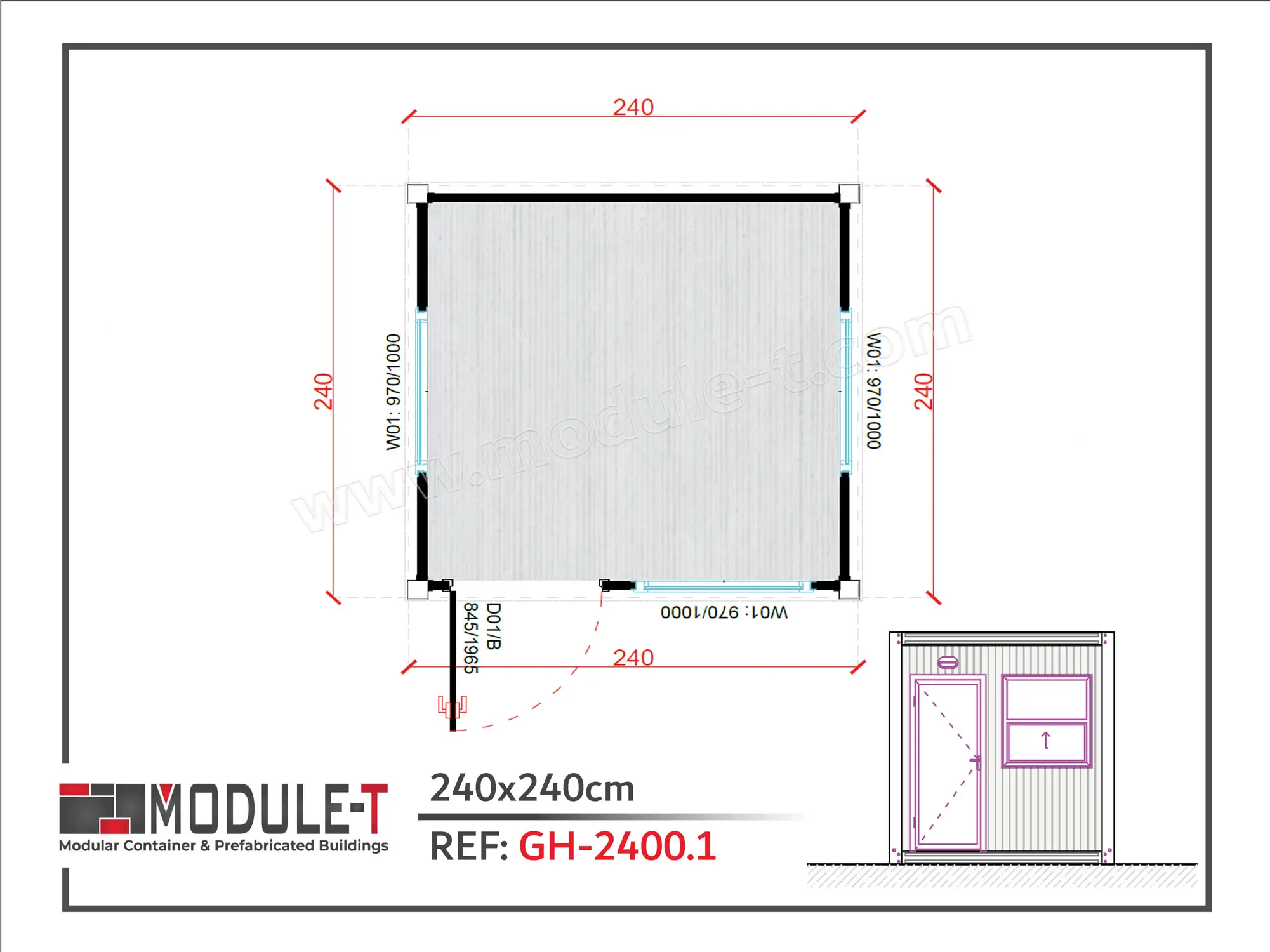

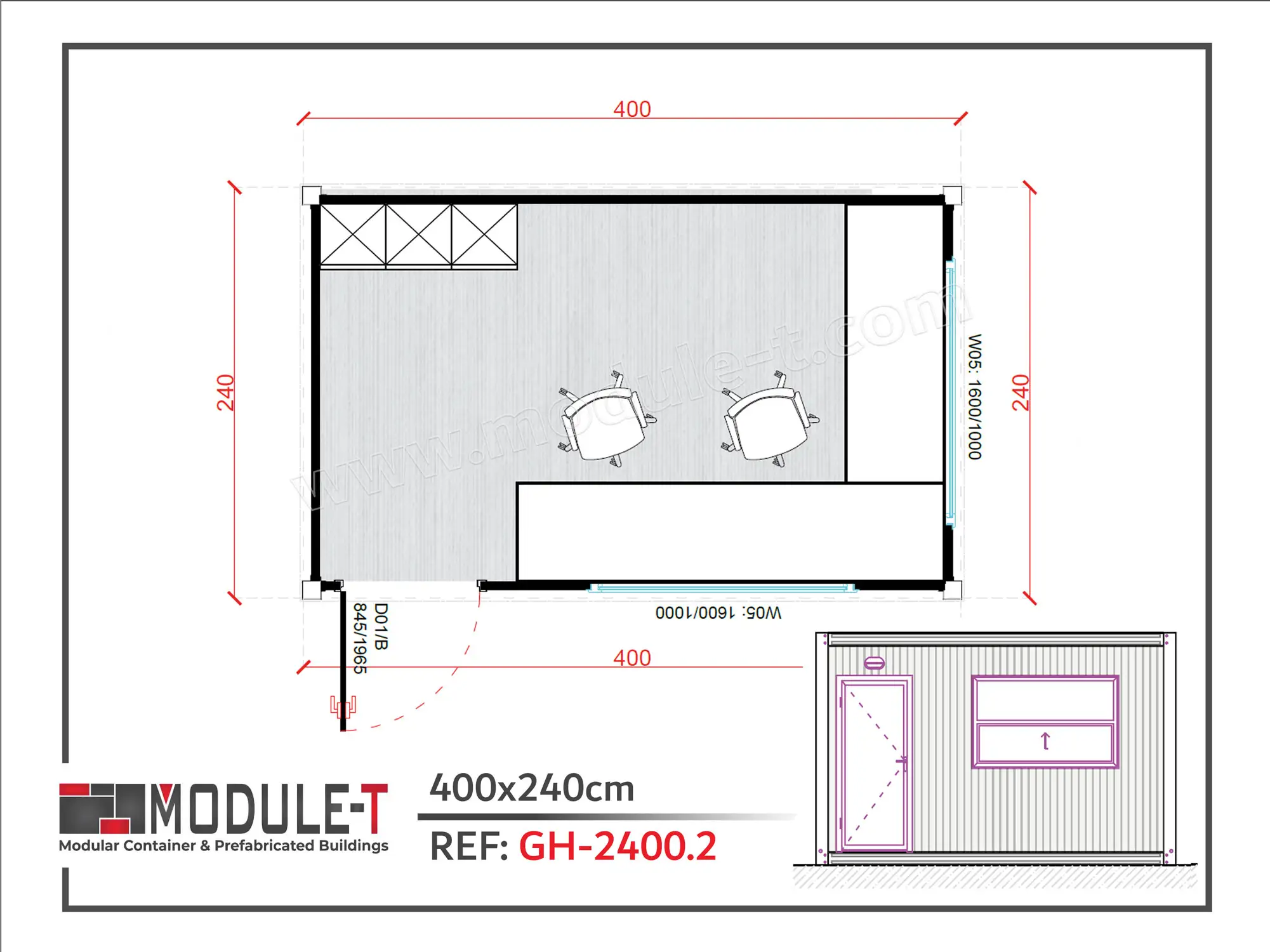

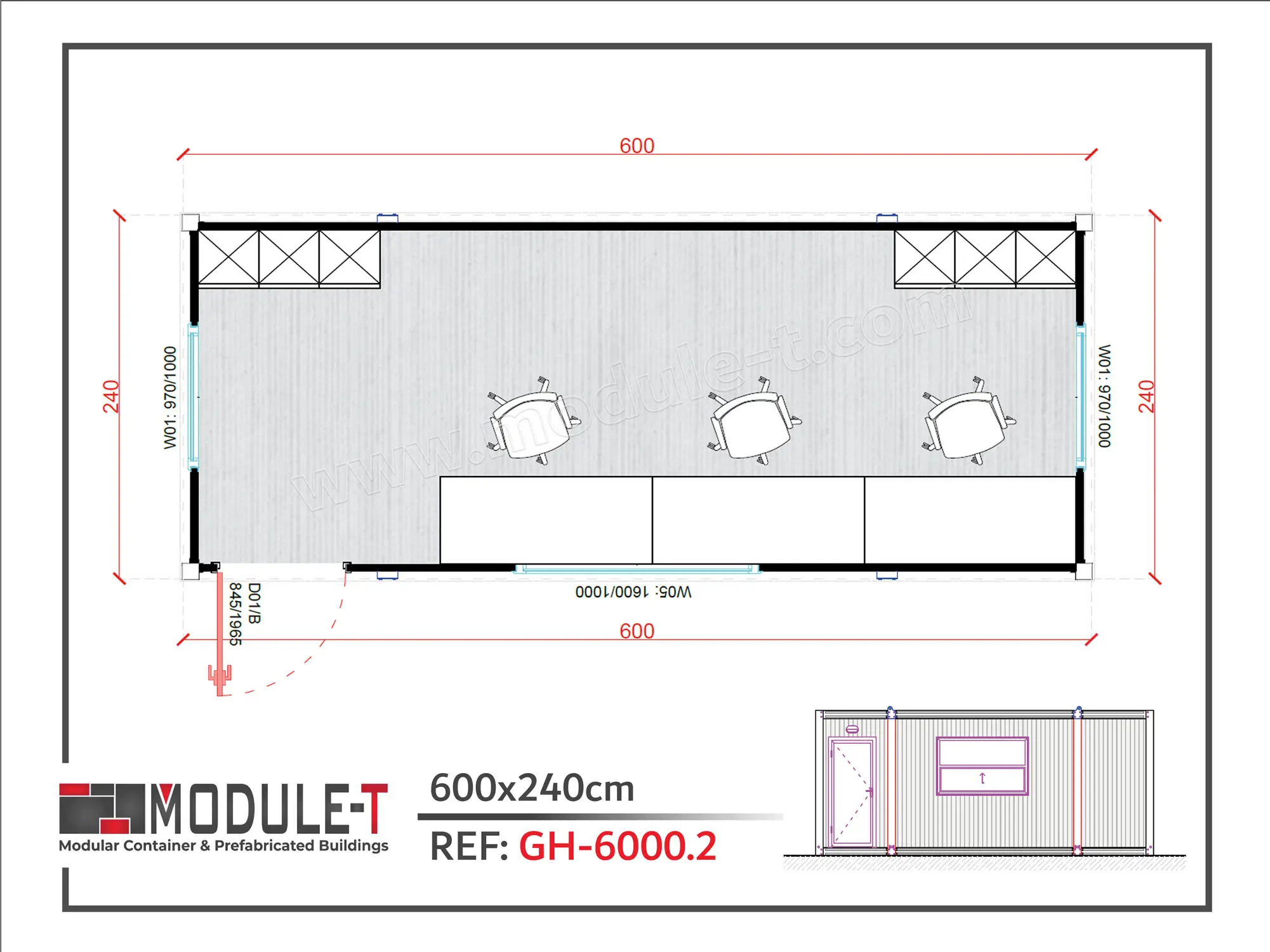

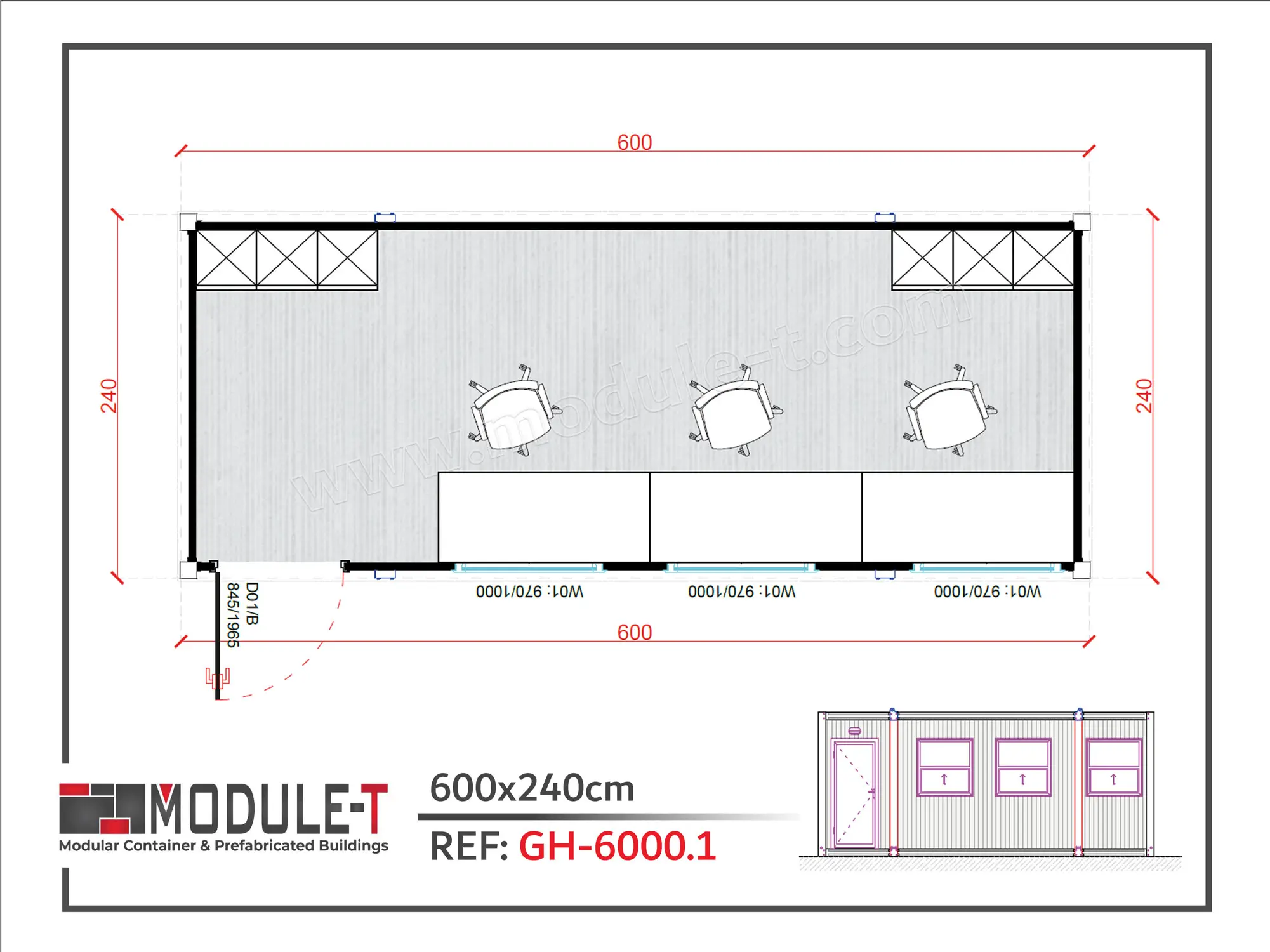

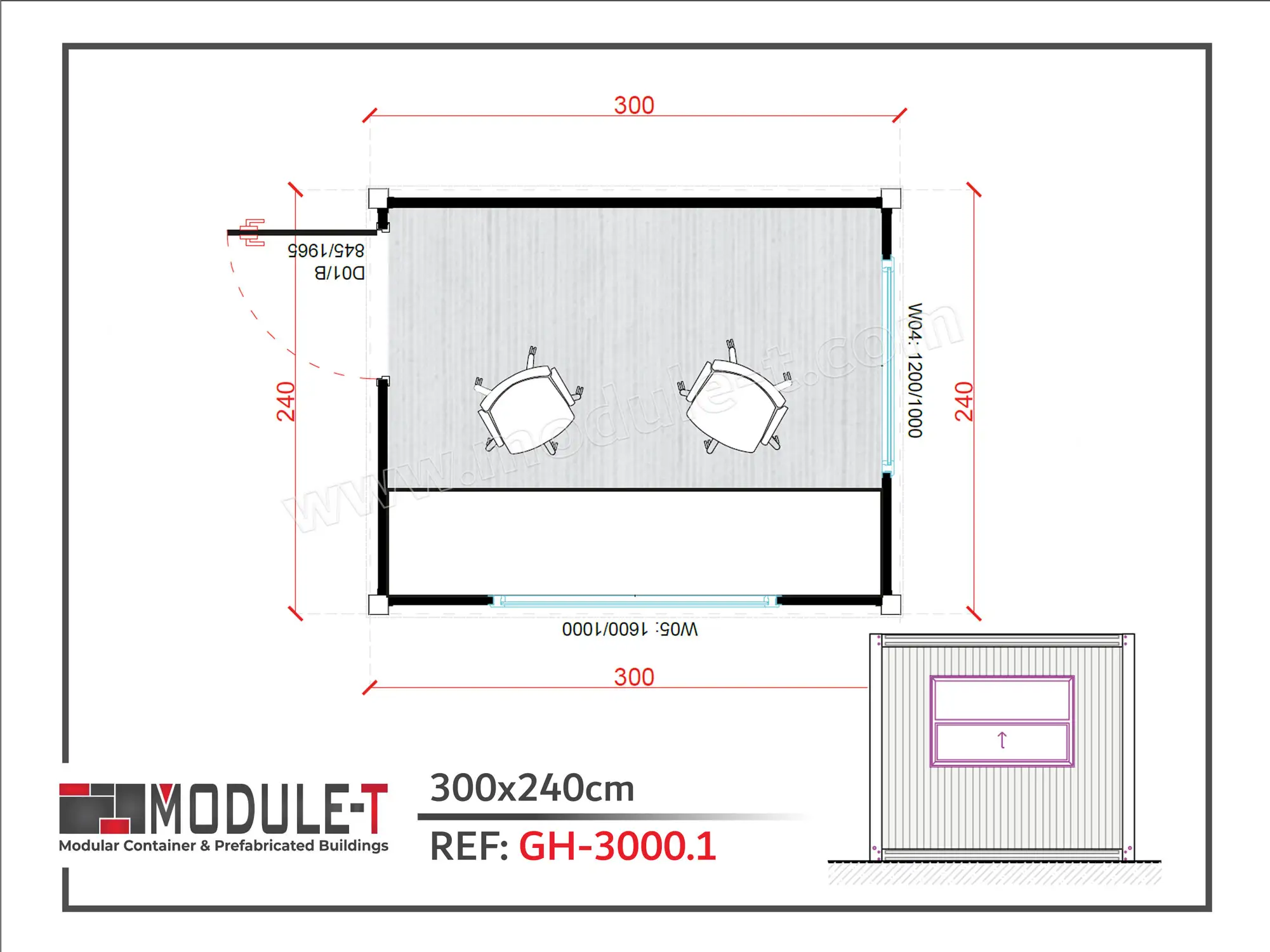

Our standard prefabricated booths for sale are 1,50 m × 1,50 m / 2,00 m × 1.50 m / 2,00 m × 2,00 m / 3,00 × 2.40 m / 6,00 m × 2,40 m, with a height of 2,60 m.

Module-T’s prefabricated booths are high-quality, affordable, and versatile. They feature steel frames and insulated sandwich panel walls, and they can be used in many ways.

These strong and secure structures are built remotely and then delivered to the site in a convenient flat-pack form that can be quickly assembled and used.

Our prefabricated booths are now common in many inner-city and remote locations worldwide. They are frequently used as cashier and payment points, security cabins and huts, point-of-sale kiosks, forecourt POS, or small office booths on temporary and permanent industrial, commercial, and construction site containers.

Prefabricated guard booths for sale are ideal for quickly creating space to protect your equipment or staff. Our prefabricated security booths’ price is attractive, as the remote manufacturing process significantly saves time, costs, and labour.

Our standard prefabricated booths for sale are 1,50 m × 1,50 m / 2,00 m × 1.50 m / 2,00 m × 2,00 m / 3,00 × 2.40 m / 6,00 m × 2,40 m, with a height of 2,60 m.

A highly galvanised and painted steel frame and surfaces with sandwich panel walls are standard. The walls are filled with a choice of rock wool, polystyrene foam, or polyurethane insulation up to 100 mm thick.

Prefab booths have PVC vinyl flooring. Options include parquet, ceramic, steel, or aluminium sheet flooring.

Standard ones have windows and doors with PVC or aluminium frames. Customisations include large oriel or sash windows, security bars, shades, and PVC or aluminium shutters.

Depending on the size and type of booth you order, a sanitary container with a WC, sink, and shower can be added.

Prefab guard shack can include many additional features. Popular options include cabling for security and monitoring equipment, manual or automatic barriers, air conditioning or heating, internet and networking sockets and cables, cabinets, desks, and storage.

Module-T is an expert in organising logistics, and our team can arrange the quick delivery of prefabricated booths to sites throughout Europe, the Middle East, Africa, the Americas, and Asia. The booths are built to be flat packed into a sea container, and they come with lifting hooks attached to allow for easy placement by crane or forklift at the site. They can be erected on beams or a light foundation, and a connection set is included. Just like our modular kiosks, most of our prefab booths take just a few hours to assemble using a few personnel and simple tools. We can arrange for a specialist assembly team to attend to large projects.

Construction site booths that can be quickly assembled and relocated as necessary on civil engineering sites. The booths can be customised to provide information points or spaces for project management, security, access control or commercial team members.

Parking, cashiers, and payment booths with windows or hatches allow attendants to talk to customers, check credentials, or take payments. These can be fitted with manual or automatic barriers or lever arms to restrict entry and exit.

Equipment booths can be supplied with or without windows to offer a secure and watertight space to store tools, machinery, and equipment.

Screening booths are typically used to separate attendants from those who may be affected by a virus yet still need to interact with the public. These were common in many areas during the pandemic and are still in use in high-risk, disaster, and high-security areas.

Premanufactured booths are built off-site using precision machinery and quality materials. This ensures that they adhere to European and American standards. The structure is also cyclonic and earthquake-resistant.

The remote manufacturing process ensures that waste materials and labour costs are kept to a minimum and that bad weather days are eliminated. This results in substantial cost and time savings.

Security guard booths for sale can be highly customised structurally and aesthetically to suit their environment and usage even as prefab booths for prefabricated school buildings.

Unlike conventional builds, prefabricated booths can be assembled, dismantled, and relocated. This makes kiosks ideal for use in temporary or time-restricted locations.

As a prominent prefabricated booth manufacturer, we understand that cost is important to clients. Our range of prefabricated booths is designed to offer premium-quality constructions at an affordable price, and the remote manufacturing process is streamlined to cut wastage and offer time and financial savings. The size, type of insulation, design alterations, and customisations you choose to include, as well as the transportation of the building to your location, will, however, influence the final price. Please contact us to learn more about our prefab booths or for a free quote.

Module-T is a market leader in the prefabricated construction industry in Turkiye and a specialist prefabricated booth manufacturer. They are just one range of many modular building ranges we produce, and our product portfolio also includes modular offices, accommodation, commercial kitchens and canteen containers, sanitary buildings, locker room containers, and shower blocks.

From our base near Istanbul, we design, manufacture, and transport our prefab security booths for sale to almost any global location. Our buildings are now in use in over 120 countries. Please contact us if you would like to know more about prefab solutions.

Yes, our prefab booths are portable, and they can be erected, dismantled, and relocated to other sites quickly.

Standard prefabricated booths come pre-cut with sockets for easy on-site electric and utility connection. During the design process, you can also include many appliances, heating and cooling systems, security features, and other fixtures.

A prefabricated kiosk is modular, and depending on the design you choose, it can be linked or stacked to other modular buildings.

Minimal foundations are required, meaning you can erect prefab booths quickly on a light cement foundation, blocks, or beams.

Our prefabricated booths meet current US and EU building standards and also adhere to current seismic and cyclonic regulations.

To receive a quote quickly, please fill in the customer request form. Our sales representatives will contact you as soon as possible.

To receive a quote quickly, please fill in the customer request form. Our sales representatives will contact you as soon as possible.