Installation:

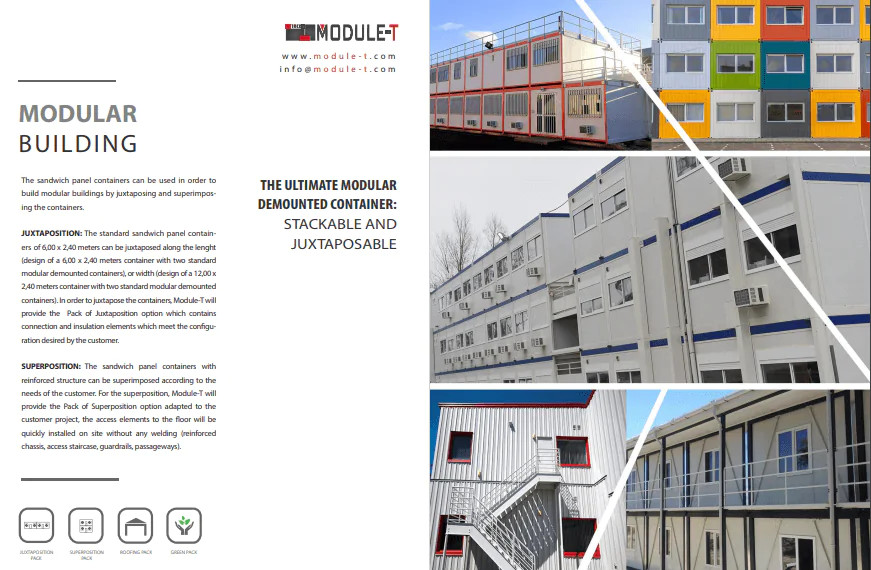

The principle of modular prefabricated buildings is the assembly of structures using prefab containers. These containers comprise a factory-prefabricated light steel frame and sandwich panel walls, making installation quick. Assembling a unit is twice as fast as its concrete equivalent. Moreover, the structure is installed on a lightweight foundation, reducing costs, especially in terms of the budget for concrete and labor. Once a project ends, the structure can be easily dismantled and reassembled on a new site.

Versatility and insulation:

Another advantage is that it is multi-functional. It can be used as a temporary building on a construction site. It can also be used as an administrative building, a refectory, an office, a school, a prefab commercial building, etc. Regarding insulation, the prefabricated modular building offers the same thermal and sound performance as traditional concrete construction. Our sandwich panels are insulated with stone wool or polyurethane up to 200 mm thick. Our system meets the insulation and safety standards of each country. The floors, ceilings, and roof also benefit from an excellent level of insulation.

Affordable price and fast delivery:

Construction solutions offer great advantages for optimizing your budget. You can realize impressive savings compared to conventional construction, up to 40% to 50%. Delivery-wise, we ship special dismantled packs by sea or land, reducing transport costs and adding to overall savings.